what is the term for the process of switching the pigs from liquid feed to solid feed

- Review

- Open up Access

- Published:

Fermented liquid feed for pigs: an ancient technique for the future

Journal of Animal Scientific discipline and Biotechnology volume 6, Commodity number:iv (2015) Cite this article

Abstract

Fermented liquid feed is feed that has been mixed with water at a ratio ranging from 1:1.5 to ane:four. By mixing with h2o, lactic acid bacteria and yeasts naturally occurring in the feed proliferate and produce lactic acid, acetic acid and ethanol which reduces the pH of the mixture. This reduction in pH inhibits pathogenic organisms from developing in the feed. In improver, when this depression pH mixture is fed, it reduces the pH in the stomach of pigs and prevents the proliferation of pathogens such equally coliforms and Salmonella in the gastrointestinal tract. For piglets, the use of fermented liquid feed offers the possibility of simultaneously providing feed and water, which may facilitate an easier transition from sow'south milk to solid feed. Secondly, offering properly produced fermented liquid feed may strengthen the role of the stomach every bit the first line of defense confronting possible pathogenic infections by lowering the pH in the alimentary canal thereby helping to exclude enteropathogens. Finally, feeding fermented liquid feed to pigs has been shown to improve the performance of suckling pigs, weaner pigs and growing-finishing pigs. In this review, electric current knowledge about the use of fermented liquid feed in pig diets will be discussed. This will include a discussion of the desirable properties of fermented liquid feed and factors affecting fermentation. In addition, advantages and disadvantages of fermented liquid feed will exist discussed including its effects on gastrointestinal health, intestinal pH and the types of bacteria institute in the alimentary canal as well as the effects of fermented liquid feeds on pig performance.

Introduction

Liquid feeding involves the employ of a nutrition prepared either from a mixture of liquid food industry by-products and conventional dry materials, or from dry raw materials mixed with h2o. By definition fermented liquid feed is feed that has been mixed with water, at a ratio ranging from 1:i.5 to 1:4, for a period long enough to achieve steady country weather. If at that place is nearly no time between mixing and feeding or the period for fermentation is as well short to reach steady state weather condition, the term liquid feed or non-fermented liquid feed is used [1].

By mixing with water, lactic acrid bacteria and yeasts naturally occurring in various feed ingredients proliferate and produce lactic acid, acerb acid and ethanol which reduces the pH of the mixture [two]. This reduction in pH inhibits pathogenic organisms from developing in the feed [iii]. In addition, when this low pH mixture is fed, information technology reduces the pH in the tummy of pigs and prevents the proliferation of pathogens such as coliforms and Salmonella from developing in the gastrointestinal tract [2].

The interest in the fermentation of feed for improving the functioning of piglets and pigs increased dramatically subsequently the announcement of the ban in the European Marriage on the use of antibiotics equally antimicrobial growth promoters for swine. The potential of fermented liquid feed, as an culling to the use of growth promoting antibiotics has been discussed in four recent reviews [1, 2, 4, 5]. In this review, contempo information about the apply of fermented liquid feed in pigs will exist provided.

Production of fermented liquid feed

Fermented liquid feed can be produced by fermenting a consummate feed or by fermentation of the grain fraction and so mixing the fermented grain with other ingredients in order to formulate a complete diet [ane]. Fermenting complete feeds is the easiest mode to produce fermented liquid feed but this method tin can be associated with some problems. The fermentation process can cause a loss of essential nutrients such as vitamins and amino acids specially synthetic amino acids which may have been added to the feed [6–ix]. Therefore, some authors advocate fermentation of the grain fraction simply instead of the complete feed [seven, 8, 10–14]. The fermented grain fraction may be used to brand a range of diets, so that "phase feeding" can be implemented using the same fermented grain. Grains are also a more than consistent product to ferment, compared with a complete feed containing multiple ingredients [8]. In add-on, fermentation of cereals often results in a more than rapid fermentation as cereals have a lower buffering capacity than compound feeds [2].

In social club to successfully control the development of pathogenic organisms, fermented liquid feed must contain adequate amounts of lactic acrid [15]. Lactic acid product can arise from spontaneous fermentation or by inoculating the feed with a culture of lactic acid leaner prior to fermentation. Spontaneous fermentation is well-nigh frequently conducted using batch fermentation. In batch fermentation, the feed and water mixture is fermented without replacement of a portion of the fermented liquid feed [11]. The advantages of this organization is that fermentation is easier to control and if undesirable fermentation occurs, it is merely one batch of feed that is ruined [eight, sixteen]. Nonetheless, batch fermentation can take several days in guild to produce a quality fermented liquid feed. In addition, under commercial farm conditions, information technology is hard to run a batch feeding system because it is virtually incommunicable to clean and sterilize the system at every filling [four].

Beal et al. [17] ended that spontaneous fermentation is non a reliable system to obtain a safe and palatable last production since variations in the pattern of fermentation occur. In addition, other studies take shown that uncontrolled/spontaneous fermentation results in college concentrations of both acetic acrid and biogenic amines which adversely affect the palatability of fermented liquid feed diets [8, ix]. Therefore, spontaneous fermentation is not advisable. All the same, should it exist necessary to use spontaneous fermentation, the quality of spontaneously fermented liquid feed tin exist improved by the add-on of copper to the fermentation medium which speeds upward lactic acid production [18].

The quality of fermented liquid feed can too be improved by the inoculation of the feed with lactic acid bacteria that rapidly produce high concentrations of lactic acid [8, 19–21]. Inoculation is particularly valuable when fermenting just the grain fraction, considering that the production of lactic acid should be higher to compensate for the dilution and buffering effects of the other feed components when incorporated into a consummate feed [7]. Bacterial strains to be used as inoculants for production must have a high capacity for lactic acid production and should be active confronting enteric pathogens [15]. Therefore, a considerable amount of enquiry has been conducted to select beneficial strains of lactic acid leaner for fermented liquid sus scrofa feed production [20, 21]. For instance, Missotten et al. [21] tested 146 strains of bacteria for their ability to control Salmonella. Bacterial species often used for inoculating feed to produce fermented liquid feed are Lactobacillus plantarum and Pediococcus spp. [1].

Another technique for ensuring adequate production of lactic acrid is a technique known equally 'back slopping' [22]. In this technique, fresh feed and water are mixed with fabric from a previously successful fermentation which acts every bit an inoculum for the new mixture [23]. This allows for the gradual selection of lactic acid leaner and an accelerated fermentation [23]. Compared with batch fermentation which takes several days to produce a quality fermented liquid feed, fermented feeds produced by back slopping tin can be fed within a few hours. Notwithstanding, Brooks [7] pointed out the possibility that this may result in the evolution of a microflora dominated by yeasts. Abundant yeast growth tin can have either negative or positive effects on the nutritive value of fermented feeds depending on the strains nowadays.

Plumed-Ferrer et al. [24] showed that maintaining 25% residuum liquid in the tank to inoculate the fresh liquid feed added to the tank was sufficient to maintain a proper fermentation. Moran et al. [12] found that at that place was no reward to keeping more 20% of the fermented wheat when performing fermentation. Therefore, although a residual retention of l% is mostly commonly used, it seems that a lower proportion can exist used with 20% being the lowest percentage which still ensures desirable feed characteristic when using dorsum slopping.

Factors affecting the quality of fermented liquid feed

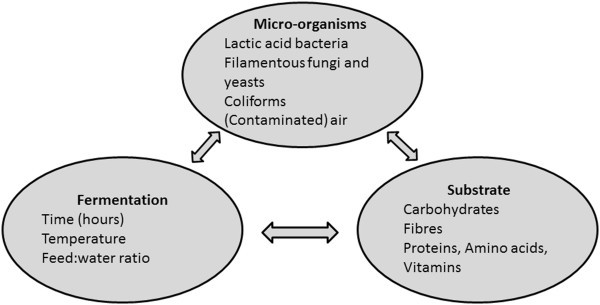

Factors affecting the quality of fermented liquid feed are displayed in Effigy i. Factors affecting the quality of the final end product include the types of micro-organisms initially present, substrate quantity and quality as well as various fermentation parameters [1, two, 25, 26].

Interactions in fermented liquid feed between the micro-organisms present, fermentation parameters and substrate quantity and quality affects the final end production. Adapted from Niba et al. [26].

The amount of lactic acid bacteria naturally nowadays on the feed or the amount of lactic acid bacteria added to the feed, determine the extent of lactic acid production. The faster this production, the faster the drop in pH and the faster pathogenic bacteria such equally Salmonella spp. or Escherichia coli can be reduced [1].

In the past few years, studies have investigated the effects of population diversity of lactic acid bacteria or yeasts in fermented liquid feed [ii, thirteen, 27–30], and a wide variation in the microbial population limerick has been reported. Lactobacillus plantarum and Pediococcus pentosaceus tend to be the near arable lactic acid bacteria strains present in fermented liquid feed [31].

Olstorpe et al. [31] reported that the composition of the bacterial species in fermented liquid feed changes during the fermentation process. They showed that Pediococcus pentosaceus was the dominant population at the beginning of a spontaneous fermentation, only later on three days of continuous fermentation, Lactobacillus plantarum became the dominant population. This was also observed in inoculated fermented liquid feed where the lactic acid leaner strain used to inoculate the feed did not remain the dominant lactic acid bacteria strain in the fermented liquid feed [i, 32].

The population diversity of yeasts present in fermented liquid feed is very high and deserves further investigation [29, 31]. In fermented liquid feed produced with wet wheat distillers' grains, whey or tap water, the dominant yeast species tended to be Pichia galeiformis, Pichia membranifaciens and Pichia anomala respectively. In a more recent study, Olstorpe et al. [33] establish another Pichia species, namely Pichia fermentans, to be the near abundant yeast species present, independent of the lactic acrid leaner culture used to inoculate the fermented liquid feed. However, Gori et al. [29] constitute that Candida milleri and Kazachstania bulderi were the predominant yeast species found in fermented liquid feed samples obtained from 40 Danish farms with an boilerplate contribution of 58.four and 17.5% to the total yeast count.

The amount of yeast present can affect the quality of fermented liquid feed. Both positive and negative effects have been reported when the fermentation is dominated by yeasts depending on the stains of yeast present [1]. Yeasts have the ability of binding enterobacteria to their surface, thereby blocking the binding of these bacteria to the gut epithelium [34]. Therefore, high concentrations of yeasts in the fermented liquid feed may be beneficial. For example, Jensen and Mikkelsen [nineteen] reported an inverse relationship between the concentration of yeast and enterobacteria in the gastrointestinal tract of pigs. In dissimilarity, a high concentration of yeast can result in the product of "off-flavours" and taints due to the product of compounds such as acetic acrid, ethanol and amylic alcohols which brand the feed less palatable [8, 35].

Plumed-Ferrer and von Wright [36] indicated that the add-on of weak acids during fermentation can successfully reduce the growth of yeasts without interfering with lactic acid leaner development. Acids that showed good results were formic acid, potassium sorbate and benzoic acid. The addition of these acids may help to reduce bug (eastward.grand. loss of free energy, reduced palatability, foaming) resulting from excessive yeast growth. A drawback to yeast product can be the production of acetic acid, 'off-flavours' and ethanol, which may diminish the palatability as well every bit the dry affair and free energy content of the feed [19].

Other parameters such as fermentation temperature, the interval betwixt and the degree of back slopping (partial replacement of fermented liquid feed past fresh liquid feed in continuous fermentation) and the feed to water ratio used can besides have an effect on the fermentation characteristics of the fermented liquid feed [viii].

The effect of unlike temperatures on the quality of fermented liquid feed was studied by Jensen and Mikkelsen [19]. They reported that fermentation of feed at temperatures in a higher place twenty°C did non provide whatsoever advantage over producing fermented liquid feed at 20°C. At 20°C, the coliform count was barely above the detection limit of three log10 CFU/1000 fermented liquid feed. Nevertheless, the authors did stress that the temperature needs to be at to the lowest degree xx°C if the required pH at feeding is to be lower than 4.5. This is because enteric pathogens, such as E. coli and Salmonella spp., do not tolerate pH values beneath four.5 [37].

Beal et al. [38] studied the event of fermentation temperature on the exclusion of Salmonella typhimurium. Their results indicated that the fourth dimension required for reduction of these bacteria was much shorter at xxx°C compared with twenty°C. Therefore, although the minimal temperature for obtaining optimal fermented liquid feed is a temperature of 20°C, a temperature of 30°C is preferable since it allows a more rapid production of lactic acrid and a more than rapid exclusion of whatever enteropathogens [xvi].

Adding cold water to the organisation should as well exist avoided with dorsum slopping. For example, adding water immediately from the tap (5-7°C) will cold-shock the organization. This could cause the induction of common cold-stupor protein formation in enteropathogens and this can protect them and allow them to persist for a longer duration in the feed [38, 39]. Furthermore, common cold-shock inhibits the growth of lactic acid leaner and allows yeasts to become dominant [39].

The feed to h2o ratio used for the product of liquid feed or fermented liquid feed can fluctuate between ane:1.5 and 1:4. From the overview given by Plumed-Ferrer and Von Wright [iv] and Niba et al. [25], it appears that the most common slurry given to pigs involves a feed to water ratio between ane:2 and ane:3.

Desirable characteristics for fermented liquid feed

Van Winsen et al. [iii] described the desirable characteristics for fermented liquid feed every bit having a pH below 4.v, lactic acrid bacteria concentrations higher up 9 log10 CFU/mL, lactic acid concentrations in a higher place 150 mmol/L and acetic acrid and ethanol concentrations below twoscore and 0.8 mmol/Fifty, respectively. Beal et al. [38] reported that in order to forbid the growth of Salmonella spp., liquid feed needs to incorporate at least 75 mmol/50 of lactic acid. Beal et al. [38] and Brooks et al. [eight] reported that in order to reduce the concentration of enterobacteria, the concentration of lactic acrid should be college than 100 mmol/L. This concentration of lactic acid can take a benign effect on feed intake, daily gain and feed efficiency [xl].

Although Van Winsen et al. [three] set the upper limit of acetic acrid at 40 mmol/L, other authors indicated that a acetic acrid concentration in a higher place 30 mmol/Fifty could already negatively touch on the palatability of fermented liquid feed [7, 8, 16]. Still, Canibe et al. [41] reported that piglets fed fermented liquid feed with added acetic acrid at levels upwards to 120 mmol/L showed no negative effects on trunk weight gain.

Effect of fermented liquid feed on the microbes in the gastrointestinal tract

The limerick of the microbial population in the gastrointestinal tract tin can exist altered by the use of fermented liquid feed. The most common change is an increase in the concentration of lactic acrid bacteria particularly in the tum and small intestine [6]. Moran et al. [12], reported that the ratio of lactic acid bacteria to coliform leaner in the lower gut of the pigs weaned using fermented liquid feed was shifted in favour of lactic acid bacteria, while in piglets fed stale feed, this ratio was shifted in favour of the coliforms.

The magnitude of the alter tin can be affected by the fermentation conditions. For example, Canibe and Jensen [6] institute no differences in the number of lactic acid bacteria present in the distal small-scale intestine of growing pigs when the gastro-intestinal content was incubated at 37°C (Table 1). However, at an incubation temperature of twenty°C (same every bit production temperature for the fermented feed), the proportions of lactic acid bacteria in the stomach and distal small intestine were significantly higher in growing pigs fed fermented liquid feed compared with dried feed or liquid feed.

Another pregnant change in the microbial population in the gastrointestinal tract is an increase in the number of yeast cells (see Table ane). Equally noted before, yeasts have the power of binding enterobacteria to their surface, thereby blocking the binding of these bacteria to the gut epithelium [34].

The increase in lactic acid bacteria and yeast cells seems to exist an fantabulous strategy to accomplish a reduction of enteropathogens such as Salmonella spp. and Due east. coli. Recently, Canibe and Jensen [2] reviewed the value of fermented liquid feed in reducing enteric diseases in pigs. From surveillance studies, it is clear that fermented liquid feed reduced the incidence of Salmonella spp. [42–45].

Issue of fermented liquid feed on pH in the alimentary canal

The results obtained in a study past Canibe and Jensen [6] indicate the changes in pH in the different segments of the gastrointestinal tract when pigs are fed fermented liquid feed, liquid feed or stale feed (Table two). The about dramatic change is a decrease in the pH in the stomach. The stomach is an important barrier confronting pathogens [46] and lowering the pH may strengthen this barrier and prevent coliform scours [47], especially in newly weaned piglets which are often incapable of producing sufficient amounts of gastric acrid [48]. In addition, Radecki et al. [49] suggested that a lower gastric pH may allow amend proteolytic activity in the breadbasket thus improving the growth of pigs fed diets containing fermented liquid feed.

In contrast to the tummy, the pH in the small intestine of piglets fed fermented liquid feed is often higher than in piglets fed stale feed or liquid feed [vi, nineteen, l, 51]. This may be related to an increased secretion of pancreatic juice, stimulated past the depression pH and loftier lactic acid concentrations in the fermented liquid feed [4, 19].

Advantages of feeding fermented liquid feed

The principle do good of feeding fermented liquid feed to pigs is that information technology improves operation. In this respect, Kil and Stein [5] accept identified fermented liquid feed as ane of the most effective feeding strategies to supersede the utilise of antibiotic growth promotors. Benign effects have been observed with suckling pigs, weaner pigs and growing-finishing pigs. The magnitude of the improvement is related to the level of pathogens present in a given swine performance.

The new born pig has a sterile gut and acquires its characteristic flora through contact with its mother and the environment [52]. Co-ordinate to Kenny et al. [53], the period immediately after birth may be the most important window for establishing a potentially benign bacterial community, which can effect in life-long, stable associations also called bacterial 'imprinting'. Feeding sows fermented liquid feed influenced the bacterial gut population of their offspring [54]. Piglets from sows fed fermented liquid feed had lower coliform counts in their feces compared with piglets from sows fed not-fermented liquid feed or dry out diets. In addition, the lactic acid bacteria counts were higher in the feces of piglets from sows fed fermented liquid feed compared with other piglets. This may exist an indication that using the correct probiotic strain for producing the fermented liquid feed may issue in microbial imprinting of the piglets' microflora and therefore it may be possible to develop a bacterial population which is resistant to adverse ecological shifts at times like weaning.

Missotten et al. [i] presented a summary of several in vivo trials performed with dry feed, liquid feed or fermented liquid feed and their effect on the performance of weaner pigs. This confirmed the conclusions made earlier by Jensen and Mikkelsen [nineteen]. In a summary of 4 trials comparing fermented liquid feed with dry feed they reported a 22.3% improvement in weight gain and a 10.nine% improvement in feed efficiency.

A do good associated with feeding diets in a liquid form is the fact that weaner pigs are provided with water and feed simultaneously [seven, 39, 55, 56]. In this manner, the piglets practise not need separate learning for feeding and drinking behaviours [48, 55]. Barber [57] indicated that while some pigs may find a drinker inside a few minutes of entering a pen, other pigs may take more than than 24 h which is of a sufficient duration to induce symptoms of dehydration.

The results obtained past Russell et al. [55] demonstrate that the dry matter intake of the newly weaned pig can be increased by providing fermented liquid feed. When piglets are offered fermented liquid feed with different dry matter percentages (14.5 to 25.v%), they maintain their dry matter intake by increasing their total volumetric intake. The dry affair concentration of the diet besides had no effect on weight gain or feed efficiency [58]. All of these studies support the theory that the pig volition limit the intake of water not originating from liquid feed or fermented liquid feed (e.g. from nipple drinkers) to maximize feed intake [59]. Therefore, the total volumetric intake of dry matter and water will be comparable when the same diet is fed in liquid or dry course [58].

Since weaner pigs oft accept a higher dry matter intake when fed liquid feed or fermented liquid feed than when fed dry diets, when formulating diets to be used equally fermented liquid feed, care should be taken to formulate on the basis of realistic estimates of dry out affair intake. Otherwise, the piglets volition consume too much of nutrients such every bit proteins which can depress feed utilization and ultimately depress dry matter intake [39] or crusade protein-induced diarrhoea [7]. Brooks [vii] pointed out that the fermentation of a nutritionally counterbalanced feed will meliorate performance but if it increases feed intake or improves gut health. If intake is unaffected, it may well be that the biochemical changes produced by fermentation will produce a diet that is less nutritionally balanced.

The benefits obtained from feeding fermented liquid feed to growing-finishing pigs are not of the same magnitude every bit those obtained with weaner pigs [1]. Jensen and Mikkelsen [19] summarized the results of 9 in vivo trials comparing the functioning of pigs fed dry feed and liquid feed and reported a iv.4% comeback in weight gain and a half-dozen.ix% improvement in feed efficiency with liquid feed. Although the improvements in operation obtained with growing-finishing pigs are non as slap-up as those obtained with weaner pigs, at that place may be benefits in terms of carcass quality. Feeding fermented liquid feed has been shown to shift the conversion of tryptophan in the hind gut towards the production of indole instead of skatole resulting in a reduction in the concentration of skatole in the backfat of fattening boars and thus reduce boar taint [60]. Plain, this do good is simply available under circumstances where intact males are used for finishing.

One explanation for the improvements in performance observed with fermented liquid feed is the control of pathogenic organisms [2]. However, another explanation may be an increase in nutrient digestibility. Although the results obtained when feeding fermented liquid feed are not straightforward, on boilerplate they seem to signal a trend towards improved digestion [61–64]. This may be inherent to the fermentation processes, where there is a thin line betwixt the germination of organic acids and activation of endogenous enzymes (e.thousand. phytase) in cereal grains which may increase digestibility and availability of certain nutrients [39, 65].

Fermentation of diets for 72 h (30-35°C) increased the ileal digestibility of crude protein, crude fibre and neutral detergent fiber and the total tract digestibility of crude protein in growing-finishing pigs [66]. One of the reasons suggested for the improved protein digestibility in pigs fed fermented liquid feed is related to the decrease in gastric pH [67]. A low gastric pH stimulates proteolytic activity in the tum and slows the rate of gastric elimination which allows more time for digestion in the tummy to accept place.

Significant improvements in the ileal digestibility of organic matter, nitrogen, and calcium have been reported in fermented liquid feed compared with dry feed [67]. A possible explanation for these increases is that feeding fermented liquid feed alters the morphology of the gastrointestinal tract [11]. Scholten et al. [xi] reported that pigs fed fermented liquid feed had significantly greater villus length and a greater villus/crypt ratio, both characteristics that are associated with increased digestive capacity.

It has also been shown that fermentation of feed tin can cause mobilization of phosphorus from phytate past activation of endogenous grain phytase [67]. As a result, Lyberg et al. [67] reported a college ileal digestibility of phosphorus in pigs fed fermented liquid feed compared with dry feed (thirty vs. 48%).

Some other reward of fermenting feed is the possibility of reducing the content of diverse antinutritional factors contained in feeds [2]. Chiang et al. [68] fermented a rapeseed meal based diet and reported a 17% reduction in isothiocyanates after ane day of fermentation and a 68% reduction subsequently 3 days of fermentation. Fermentation of beans for 96 h reduced the concentration of antinutritional factors such as α-galactosides, phytate, trypsin inhibitor, tannins and saponins [69]. This was besides seen in the study of Egounlety and Aworh [70] for fermentations of soybean, cowpea and groundbean. However, during the soybean fermentation the trypsin inhibitor increased slightly.

Reductions in the amount of dust in pig barns during handling and feeding have been reported with fermented liquid feeding [1]. Such a reduction non only improves the environment for pigs and workers but can assist to exacerbate the impact of respiratory diseases on pig performance.

Disadvantages of fermented liquid feeding

Although in that location are many advantages to the employ of fermented liquid feed, there are also disadvantages. Liquid feeding is sometimes associated with the development of diseases such as haemorrhagic bowel syndrome, gastric torsion, gastrointestinal tympany and gastric ulcers [1, 7]. In addition, the fermentation process tin can cause a loss of essential nutrients from the feed particularly constructed amino acids deliberately added to the feed [6–9]. For example, the product of biogenic amines, such as cadaverine can occur as a result of decarboxylation of synthetic L-lysine, [8, 9]. Biogenic amine formation causes an irreversible loss of amino acids for the pig [71, 72]. The affect of this loss can exist reduced by fermentation of the grain fraction only rather than the consummate feed. Finally, if the feed is not properly fermented, a loftier concentration of yeast can result in the product of "off-flavours" and taints due to the production of compounds such as acerb acid, ethanol and amylic alcohols which make the feed less palatable [8, 37].

Conclusions

Feeding fermented liquid feed to pigs has been shown to improve the performance of suckling pigs, weaner pigs and growing-finishing pigs. By reducing the pH in the stomach of pigs, feeding fermented liquid feed prevents the proliferation of pathogens such equally coliforms and Salmonella from developing in the gastrointestinal tract. Boosted benefits from liquid feeding include an increase in nutrient digestibility, improved intestinal morphology, a reduction in the content of diverse antinutritional factors in feeds and a reduction in grit levels in swine barns. Nevertheless, liquid feeding is sometimes associated with the development of diseases such as haemorrhagic bowel syndrome, gastric torsion, gastrointestinal tympany and gastric ulcers. In addition, the fermentation process tin can cause a loss of essential nutrients from the feed especially synthetic amino acids. Finally, if the feed is non properly fermented, a high concentration of yeast tin can result in the product of "off-flavours" and taints due to the product of compounds such as acetic acrid, ethanol and amylic alcohols which make the feed less palatable. On residue, the use of fermented liquid feed appears to be a price effective alternative to the use of antibiotic growth promoters.

References

-

Missotten JAM, Michiels J, Ovyn A, De Smet S, Dierick NA: Fermented liquid feed for pigs. Curvation Anim Nutr 2010, 64:437–66. 10.1080/1745039X.2010.512725

-

Canibe Due north, Jensen BB: Fermented liquid feed – microbial and nutritional aspects and impact on enteric diseases in pigs. Anim Feed Sci Technol 2012, 173:17–40. 10.1016/j.anifeedsci.2011.12.021

-

Van Winsen RL, Urlings BAP, Lipman LJA, Snijders JMA, Keuzenkamp D, Verheijden JHM, et al.: Effect of fermented feed on the microbial population of the gastrointestinal tracts of pigs. Appl Environ Microbiol 2001, 67:3071–half dozen. ten.1128/AEM.67.7.3071-3076.2001

-

Plumed-Ferrer C, Von Wright A: Fermented pig liquid feed: nutritional, safe and regulatory aspects. J Appl Microbiol 2009, 106:351–68. 10.1111/j.1365-2672.2008.03938.x

-

Kil DY, Stein HH: Invited review: management and feeding strategies to ameliorate the impact of removing antibiotic growth promotors from diets fed to weanling pigs. Can J Anim Sci 2010, xc:447–60. x.4141/cjas10028

-

Canibe N, Jensen BB: Fermented and not-fermented liquid feed to growing pigs: effect on aspects of gastrointestinal ecology and growth performance. J Anim Sci 2003, 81:2019–31.

-

Brooks PH: Fermented liquid feed for pigs. CAB Rev 2008, 3, north° 073:18.

-

Brooks PH, Beal JD, Niven S, Demečková V: Liquid feeding of pigs II. Potential for improving pig health and food rubber. Animal Science Papers and Reports. Presented at the Briefing: Effect of Genetic and Non-genetic Factors on Carcass and Meat Quality of Pigs; 24–25 April 2003; Siedlce, Poland, vol 21 (Suppl 1) 2003, 23–39.

-

Niven SJ, Aggravate JD, Brooks PH: The result of controlled fermentation on the fate of constructed lysine in liquid diets for pigs. Anim Feed Sci Technol 2006, 129:304–15. 10.1016/j.anifeedsci.2005.12.016

-

Pedersen AO, Maribo H, Jensen BB, Hansen ID, Aaslyng MD: Fermented grain in liquid feed for heavy pigs. In Report No. 547. Copenhagen: The National Committee for Squealer Production, Danish Salary and Meat Council; 2002.

-

Scholten RHJ, van der Peet-Schwering CMC, den Hartog LA, Balk M, Schrama JW, Verstegen WMA: Fermented wheat in liquid diets: furnishings on gastrointestinal characteristics in weanling piglets. J Anim Sci 2002, 80:1179–86.

-

Moran CA, Scholten RHJ, Tricarico JM, Brooks PH, Verstegen MWA: Fermentation of wheat: effects of dorsum slopping different proportions of pre-fermented wheat on the microbial and chemical composition. Arch Anim Nutr 2006, threescore:158–69. ten.1080/17450390600562700

-

Canibe N, Højberg O, Badsberg JH, Jensen BB: Effect of feeding fermented liquid feed and fermented grain on gastrointestinal environmental and growth functioning in piglets. J Anim Sci 2007, 85:2959–71. 10.2527/jas.2006-744

-

Canibe Due north, Jensen BB: Fermented liquid feed and fermented grain to piglets- Effect on gastrointestinal ecology and growth functioning. Livest Sci 2007, 108:198–201. x.1016/j.livsci.2007.01.095

-

Van Winsen RL, Lipman LJA, Biesterveld S, Urlings BAP, Snijders JMA, Van Knapen F: Machinery of Salmonella reduction in fermented pig feed. J Sci Food Agr 2000, 81:342–6.

-

Brooks PH: Liquid feeding as a means to promote pig wellness. London Swine Conference - Maintaining Your Competitive Edge, 9–10 April 2003; London 2003, 83–103.

-

Beal JD, Niven SJ, Brooks PH, Gill BP: Variation in short concatenation fatty acid and ethanol concentration resulting from the natural fermentation of wheat and barley for inclusion in liquid diets for pigs. J Sci Food Agr 2005, 85:433–40. 10.1002/jsfa.2013

-

Aggravate JD, Niven SJ, Campbell A, Brooks PH: The result of copper on the death rate of Salmonellla typhimurium DT104: 30 in food substrates acidified with organic acids. Lett Appl Microbiol 2003, 38:eight–12.

-

Jensen BB, Mikkelsen LL: Feeding liquid diets to pigs. In Recent Advances in Animal Diet. Edited past: Garnsworthy PC, Wiseman J. Nottingham, UK: Nottingham University Printing; 1998:107–26.

-

Missotten JAM, Michiels J, Goris J, Herman L, Heyndrickx M, De Smet S, et al.: Screening of two probiotic products for utilize in fermented liquid feed. Livest Sci 2007, 108:232–5. 10.1016/j.livsci.2007.01.078

-

Missotten JAM, Goris J, Michiels J, Van Coillie E, Herman L, De Smet South, et al.: Screening of isolated lactic acid bacteria equally potential beneficial strains for fermented liquid pig feed production. Anim Feed Sci Technol 2009, 150:122–38. ten.1016/j.anifeedsci.2008.08.002

-

Salovaara H: Lactic acid bacteria in cereal-based products. In Lactic Acid Bacteria: Microbiology and Functional Aspects. 2d edition. Edited by: Salminen Due south, Von Wright A. New York, United states of america: Marcel Dekker; 1998:115–37.

-

Nout MJR, Rombouts FM, Havelaar A: Effects of accelerated natural lactic fermentation of infant food ingredients on some pathogenic microorganisms. Int J Food Microbiol 1989, 8:351–61. 10.1016/0168-1605(89)90006-eight

-

Plumed-Ferrer C, Kivelä I, Hyvönen P, Von Wright A: Survival, growth and persistence under farm conditions of a Lactobacillus plantarum strain inoculated into liquid pig feed. J Appl Microbiol 2005, 99:851–8. 10.1111/j.1365-2672.2005.02666.10

-

Niba AT, Beal JD, Kudi AC, Brooks PH: Potential of bacterial fermentation as a biosafe method of improving feeds for pigs and poultry. Afr J Biotechnol 2009, 8:1758–67.

-

Choct M, Selby EAD, Cadogan DJ, Campbell RG: Event of liquid feed ratio, steeping fourth dimension, and enzyme supplementation on the performance of weaner pigs. Aust J Agr Res 2004, 55:247–52. 10.1071/AR03106

-

Plumed-Ferrer C, Llopis M, Hyvönen P, Von Wright A: Characterization of the microbial community and its changes in liquid piglet feed formulations. J Sci Food Agr 2004, 84:1315–eight. x.1002/jsfa.1818

-

Pedersen C, Johnsson H, Lindberg JE, Roos S: Microbiological label of wet wheat distillers' grain, with focus on isolation of Lactobacilli with potential as probiotics. Appl Environ Microbiol 2004, 70:1522–7. x.1128/AEM.70.3.1522-1527.2004

-

Gori M, Bjørklund MK, Canibe Due north, Pedersen AØ, Jespersen L: Occurrence and identification of yeast species in fermented liquid feed for piglets. Microb Ecol 2011, 61:146–53. 10.1007/s00248-010-9706-6

-

Hong TTT, Passoth Five, Lindberg JE: Bacterial diversity at different sites of the digestive tract of weaned piglets fed liquid diets. Asian Austral J Anim 2011, 24:834–43. 10.5713/ajas.2011.10291

-

Olstorpe Thou, Lyberg K, Lindberg JE, Schnürer J, Passoth Five: Population diversity of yeasts and lactic acid leaner in pig feed fermented with whey, wet wheat distillers' grains, or h2o at different temperatures. Appl Environ Microbiol 2008, 74:1696–703. 10.1128/AEM.02231-07

-

Geary TM, Brooks PH, Beal JD, Campbell A: Effect on weaner hog operation and diet microbiology of feeding a liquid diet acidified to pH 4 with either lactic acid or through fermentation with Pediococcus acidilactici . J Sci Food Agr 1999, 79:633–40.

-

Olstorpe Grand, Axelsson Fifty, Schnürner J, Passoth V: Effect of starter culture inoculation on feed hygiene and microbial population development in fermented sus scrofa feed equanimous of cereal grain mix with wet wheat distillers' grain. J Appl Microbiol 2010, 108:129–38. 10.1111/j.1365-2672.2009.04399.x

-

Mul AJ, Perry FG: The function of fructo-oligosaccharides in animal diet. In Contempo Advances in Animal Diet. Edited by: Garnsworthy PC, Cole DJA. Nottingham, Uk: Nottingham University Press; 1994:54–79.

-

Moran CA: Evolution and benefits of liquid diets for newly weaned pigs. In PhD Thesis. Plymouth, England: University of Plymouth; 2001.

-

Plumed-Ferrer C, Von Wright A: Antimicrobial action of weak acids in liquid feed fermentations, and its effects on yeasts and lactic acrid bacteria. J Sci Nutrient Agr 2011, 91:1032–40. 10.1002/jsfa.4278

-

Merrell DS, Camilli A: Acrid tolerance of gastrointestinal pathogens. Curr Opin Microbiol 2002, 5:51–5. 10.1016/S1369-5274(02)00285-0

-

Beal JD, Niven SJ, Campbell A, Brooks PH: The result of temperature on the growth and persistence of Salmonella in fermented liquid pig feed. Int J Food Microbiol 2002, 79:99–104. 10.1016/S0168-1605(02)00183-6

-

Brooks PH, Beal JD, Niven S: Liquid feeding of pigs I. Potential for reducing environmental impact and for improving productivity. Animal Science Papers and Reports. Presented at the Conference: Effect of Genetic and Non-genetic Factors on Carcass and Meat Quality of Pigs; 24–25 April 2003; Siedlce, Poland, vol 21(Suppl ane) 2003, vii–22.

-

Roth FX, Kirchgessner M: Organic acids as feed additive for immature pigs: Nutritional and gastrointestinal furnishings. J Anim Feed Sci 1998, vii:25–33.

-

Canibe Due north, Pedersen AØ, Jensen BB: Impact of acetic acrid concentration of fermented liquid feed on growth performance of piglets. Livest Sci 2010, 133:117–9. x.1016/j.livsci.2010.06.040

-

Tielen MJM, Van Schie FW, Van der Wolf PJ, Elbers ARW, Koppens JMCC, Wolbers WB: Hazard factors and control measures for subclinical salmonella infection in pig herds. In Proceedings of the 2d International Symposium on Epidemiology and Control of Salmonella in Pork. Edited past: Bech-Nielsen S, Nielsen JP. Copenhagen, Denmark: Federation of Danish Pig Producers and Slaughterhouses; 1997:32–5.

-

Lo Fo Wong DMA, Dahl J, Wingstrand A, Van der Wolf PJ, Von Altrock A, Thorberg BM: A European longitudinal study in Salmonella seronegative and seropositive-classified finishing pig herds. Epidemiol Infect 2004, 132:903–xiv. ten.1017/S095026880400264X

-

Van der Wolf PJ, Bongers JH, Elbers ARW, Franssen FMMC, Hunneman WA, Van Exsel ACA, et al.: Salmonella infections in finishing pigs in the Netherlands: bacteriological herd prevalence, serogroup and antibiotic resistance of isolates and run a risk factors for infection. Vet Microbiol 1999, 67:263–75. ten.1016/S0378-1135(99)00054-1

-

Van der Wolf PJ, Wolbers WB, Elbers ARW, Van der Heijden HMJF, Koppen JMCC, Hunneman WA, et al.: Herd level husbandry factors associated with the serological Salmonella prevalence in finishing squealer herds in kingdom of the netherlands. Vet Microbiol 2001, 78:205–19. 10.1016/S0378-1135(00)00294-seven

-

Lallès J-P, Bosi P, Smidt H, Stokes CR: Weaning – a claiming to gut physiologists. Livest Sci 2007, 108:82–93. 10.1016/j.livsci.2007.01.091

-

Easter RA, Cole DJA, Haresign W, Garnsworthy PC: Acidification of diets for pigs. In Recent Developments in Hog Nutrition two. Nottingham, Uk: Nottingham University Press; 1993:256–66.

-

Partridge GG, Gill BP, Garnsworthy PC, Cole DJA: New approaches with pig weaner diets. In Recent Advances in Animal Nutrition. Nottingham, Britain: Nottingham University Press; 1993:221–48.

-

Radecki SV, Juhl MR, Miller ER: Fumaric and citric acids every bit fed additives in starter pig diets: consequence on functioning and nutrition rest. J Anim Sci 1988, 66:2598–605.

-

Mikkelsen LL, Jensen BB: Performance and microbial action in the gastrointestinal tract of piglets fed fermented liquid feed at weaning. J Anim Feed Sci 1998, 7:211–5.

-

Mikkelsen LL, Jensen BB: Effect of fermented liquid feed on the activeness and composition of the microbiota in the gut of pigs. Pig News Inform 2000,21(Suppl N):59–66.

-

Konstantinov SR, Awati AA, Williams BA, Miller BG, Jones P, Stokes CR, et al.: Post-natal development of the porcine microbiota composition and activities. Environ Microbiol 2006, 8:1191–ix. ten.1111/j.1462-2920.2006.01009.x

-

Kenny M, Smidt H, Mengheri East, Miller B: Probiotics – Do they take a role in the sus scrofa industry. Animal 2011, 5:462–seventy. ten.1017/S175173111000193X

-

Demečková V, Kelly D, Coutts AGP, Brooks PH, Campbell A: The consequence of fermented liquid feeding on the faecal microbiology and colostrum quality of farrowing sows. Int J Food Microbiol 2002, 79:85–97. 10.1016/S0168-1605(02)00182-4

-

Russell P, Geary T, Brooks P, Campbell A: Functioning, h2o use and effluent output of weaner pigs fed ad libitum with either dry pellets or liquid feed and the role of microbial action in the liquid feed. J Sci Food Agr 1996, 72:8–xvi.

-

Brooks PH, Tsourgiannis CA: Factors affecting the voluntary feed intake of the weaned sus scrofa. In Weaning the Pig, Concepts and Consequences. Edited by: Pluske JR, Le Dividich J, Verstegen MWA. Wageningen, The Netherlands: Wageningen Academic Publishers; 2003:81–116.

-

Barber J: The rationalisation of drinking water supplies for pig housing. In PhD Thesis. Plymouth, England: Polytechnic South W; 1992.

-

Geary TM, Brooks PH, Morgan DT, Campbell A, Russell PJ: Performance of weaner pigs fed ad libitum with liquid feed at different dry matter concentrations. J Sci Food Agr 1996, 72:17–24.

-

Yang TS, Howard Exist, McFarlane WV: Furnishings of food on drinking behaviour of growing pigs. Appl Anim Ethol 1981, seven:259–70. 10.1016/0304-3762(81)90082-1

-

Kjeldsen H: Practical experience with production and slaughter of entire male person pigs. INRA, Paris, France, Les Colques NO threescore137–44.

-

Pedersen C, Stein HH: Effects of liquid and fermented liquid feeding on energy, dry matter, protein and phosphorus digestibility past growing pigs. Livest Sci 2010, 134:59–61. 10.1016/j.livsci.2010.06.097

-

Jørgensen H, Sholly D, Pedersen AØ, Canibe N, Bach Knudsen KE: Fermentation of cereals – Influence on digestibility of nutrients in growing pigs. Livest Sci 2010, 134:56–8. 10.1016/j.livsci.2010.06.096

-

Bruininx EMAM, Binnendijk GP, Zandstra T, Heetkamp MJW, van der Peet-Schwering CMC, Gerrits WJJ: Performance and energy metabolism in restrictively fed weanling pigs are not affected by feed in either fermented cereals or their end-products. J Anim Phys Anim Nutr 2010,94(Suppl East):355–65.

-

Cho JH, Zhang ZF, Kim IH: Effects of fermented grains as raw cereal substitutes on growth functioning, nutrient digestibility, blood profiles, and fecal baneful gas emission in growing pigs. Livest Sci 2013, 154:131–6. 10.1016/j.livsci.2013.03.011

-

Brooks PH: The potential of liquid feeding systems. In Concepts in Sus scrofa Science, The 1st Almanac Turtle Lake Pig Science Conference Edited by: Lyons TP, Cole DJA. 1999, 81–98.

-

Hong TTT, Lindberg JE: Effect of cooking and fermentation of a grunter nutrition on gut environment and digestibility in growing pigs. Livest Sci 2007, 109:135–7. 10.1016/j.livsci.2007.01.121

-

Lyberg K, Lundh T, Pedersen C, Lindberg JE: Influence of soaking, fermentation and phytase supplementation on food digestibility in pigs offered a grower diet based on wheat and barley. Anim Sci 2006, 82:853–8. 10.1017/ASC2006109

-

Chiang G, Lu WQ, Pioa XS, Hu JK, Gong LM, Thacker PA: Effects of feeding solid-state fermented rapeseed meal on functioning, nutrient digestibility, and intestinal morphology of broiler chickens. Asian Austral J Anim 2010, 23:263–71.

-

Shimelis EA, Rakshit SK: Influence of natural and controlled fermentations on alpha-galactosides, anti-nutrients and protein digestibility of beans (Phaseolus vulgaris L.). Int J Food Sci Technol 2008, 43:658–65. x.1111/j.1365-2621.2006.01506.ten

-

Egounlety Yard, Aworh OC: Result of soaking, dehulling, cooking and fermentation with Rhizopus oligosporus on the oligosaccharides, trypsin inhibitor, phytic acid and tannins of soybean ( Glycine max Merr.), cowpea ( Vigna unguiculata L. Walp) and groundbean ( Macrotyloma geocarpa Harms). J Nutrient Eng 2003, 56:249–54. ten.1016/S0260-8774(02)00262-5

-

Dierick NA, Vervaeke IJ, Decuypere JA, Henderickx HK: Influence of the gut flora and of some growth-promoting feed additives on nitrogen metabolism in pigs. I: Studies in vitro. Livest Prod Sci 1986, xiv:161–76. x.1016/0301-6226(86)90005-9

-

Dierick NA, Vervaeke IJ, Decuypere JA, Henderickx HK: Influence of the gut flora and of some growth-promoting feed additives on nitrogen metabolism in pigs. 2: Studies in vivo. Livest Prod Sci 1986, xiv:177–93. 10.1016/0301-6226(86)90006-0

Author information

Affiliations

Corresponding author

Boosted data

Competing interests

The authors declare they accept no competing interests.

Authors' contribution

JAMM carried out the literature study and drafted the manuscript. JM, JD and SDS critically evaluated the manuscript. All authors read and approved the final manuscript.

Rights and permissions

This article is published under license to BioMed Central Ltd. This is an Open up Admission article distributed nether the terms of the Creative Commons Attribution License (http://creativecommons.org/licenses/by/4.0), which permits unrestricted employ, distribution, and reproduction in any medium, provided the original work is properly credited. The Creative Eatables Public Domain Dedication waiver (http://creativecommons.org/publicdomain/naught/one.0/) applies to the data made available in this commodity, unless otherwise stated.

Reprints and Permissions

Well-nigh this article

Cite this article

Missotten, J.A., Michiels, J., Degroote, J. et al. Fermented liquid feed for pigs: an ancient technique for the time to come. J Fauna Sci Biotechnol six, four (2015). https://doi.org/10.1186/2049-1891-six-4

-

Received:

-

Accepted:

-

Published:

-

DOI : https://doi.org/10.1186/2049-1891-6-four

Keywords

- Fermented liquid feed

- Lactobacillus spp

- Pigs

- Probiotics

- Yeasts

mitchellnortrinter.blogspot.com

Source: https://jasbsci.biomedcentral.com/articles/10.1186/2049-1891-6-4

0 Response to "what is the term for the process of switching the pigs from liquid feed to solid feed"

Post a Comment